Loading... Please wait...

Loading... Please wait...-

Call Us (877) 427-2739

- Our Story

- Contact Us

- Fastener News Desk

- Nut and BLOG

- My Account

- Items / $0.00

All prices are in All prices are in USD

Categories

- Home

- Nut and BLOG

- Make Youngstown 2016 | The Movers, Shakers and Makers in Youngstown, Ohio

Make Youngstown 2016 | The Movers, Shakers and Makers in Youngstown, Ohio

Posted by Hudson Fasteners, Inc. on 2nd May 2016

In earlier times in history, printing something meant that it was flat on a paper, but today the idea of printing goes way beyond that. Printing now includes 3D printing, which involves either adding or subtracting materials to create an object, shape or the like. The technology is being utilized in many industries such as manufacturing, aerospace, fashion, art, prototyping end products, by makers at home and in tech shops. The phenomenon of 3D printing is still fairly new, but it provides a lot of opportunity to be a game changer for the future of making and manufacturing.

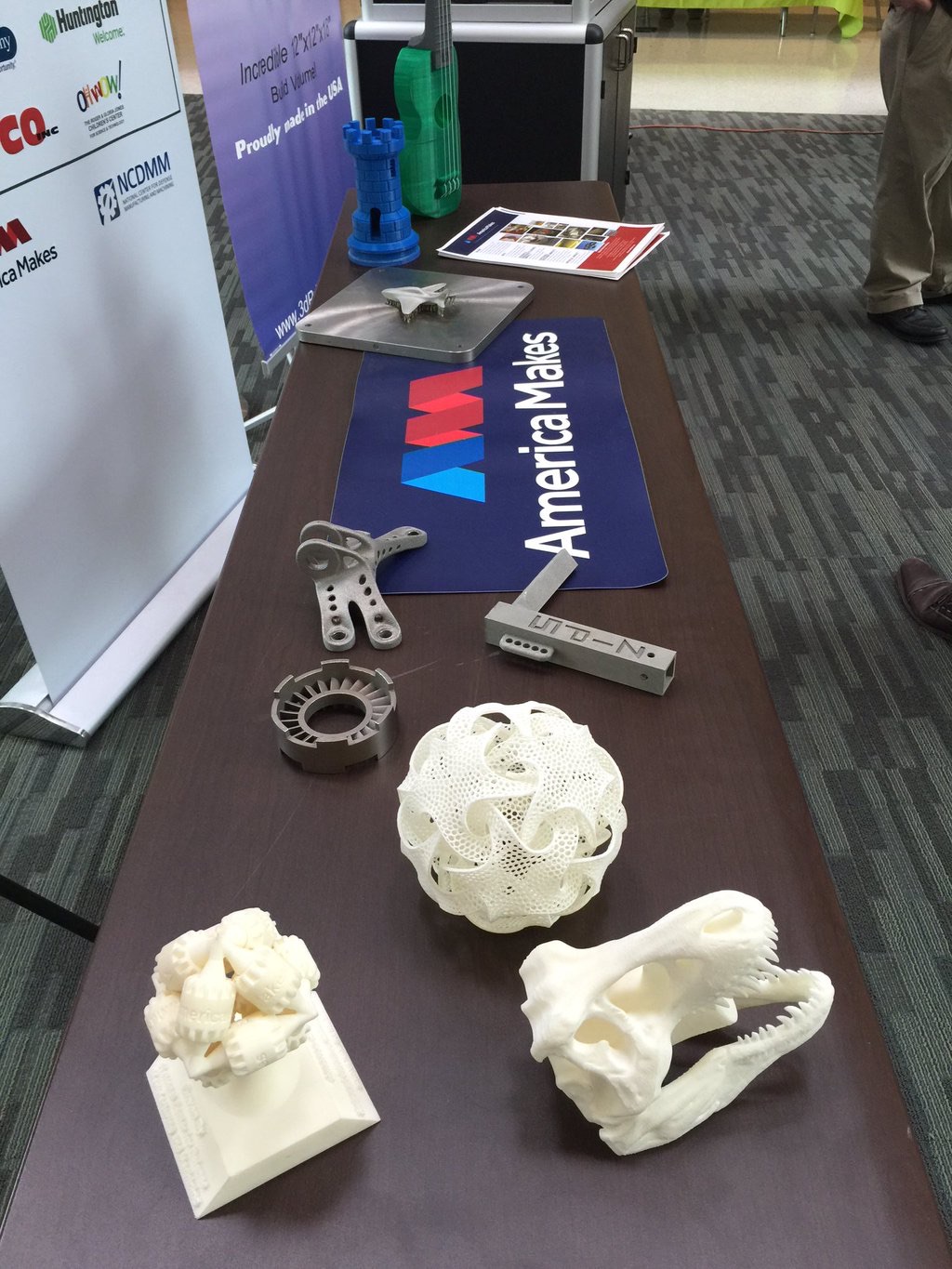

Hudson Fasteners had the opportunity to attend Make Youngstown, an event held in Youngstown, Ohio at the Youngstown State University Williamson College of Business. Youngstown’s history is as strong as steel in both manufacturing and entrepreneurialism. Youngstown is also the home of the first National Network for Manufacturing Innovation known as America Makes, the national accelerator for additive manufacturing (AM) and 3D printing (3DP); Youngstown State University became the first STEM College in Ohio; and a World Class technology incubator: the Youngstown Business Incubator.

We spoke with a variety of the exhibitors at the event who either own, or are a part of a business that promotes 3D printing, additive manufacturing and the maker community.

Rich Wetzel, Additive Manufacturing Business Coordinator for the Youngstown Business Incubator, organized the event and believes there are a lot of great opportunities available to students within additive manufacturing. He sees benefit in areas like Youngstown which have lost manufacturing jobs. “I think it really enables a lot of people in the community to learn about the opportunities that are being developed right here in the valley,” Rich says. With Youngstown State University’s connection and proximity to both the Youngstown Business Incubator and America Makes, students have the opportunity to invest in the 3D printing industry and he encourages them to take risks.

Rich Wetzel was one of many at Make Youngstown who sees the benefit of additive

manufacturing in the Valley. Taylor Monroe of Printing

3D Parts believes that the core of

engineering was lost when the steel mills closed, however, he thinks additive

manufacturing could bring about a bright future for the area. “I think this is a great opportunity to

revitalize Youngstown’s economy,” he says, believing that this could be the key

to retaining many of the talented engineers that Youngstown State University is

producing in this area.

“The passion of America used to be inventing new things,” says Jessie Tuscano

of Bravura

3D. While manufacturing has its

benefits, she believes that traditional manufacturing can limit startups and

inventors due to cost and global competitiveness. 3D printing, however, has a

lot of opportunities. With 3D printing, prototypes are possible and new ideas

can be conceived. Now, small to medium companies have ways to manufacture products

which they could not have done previously.

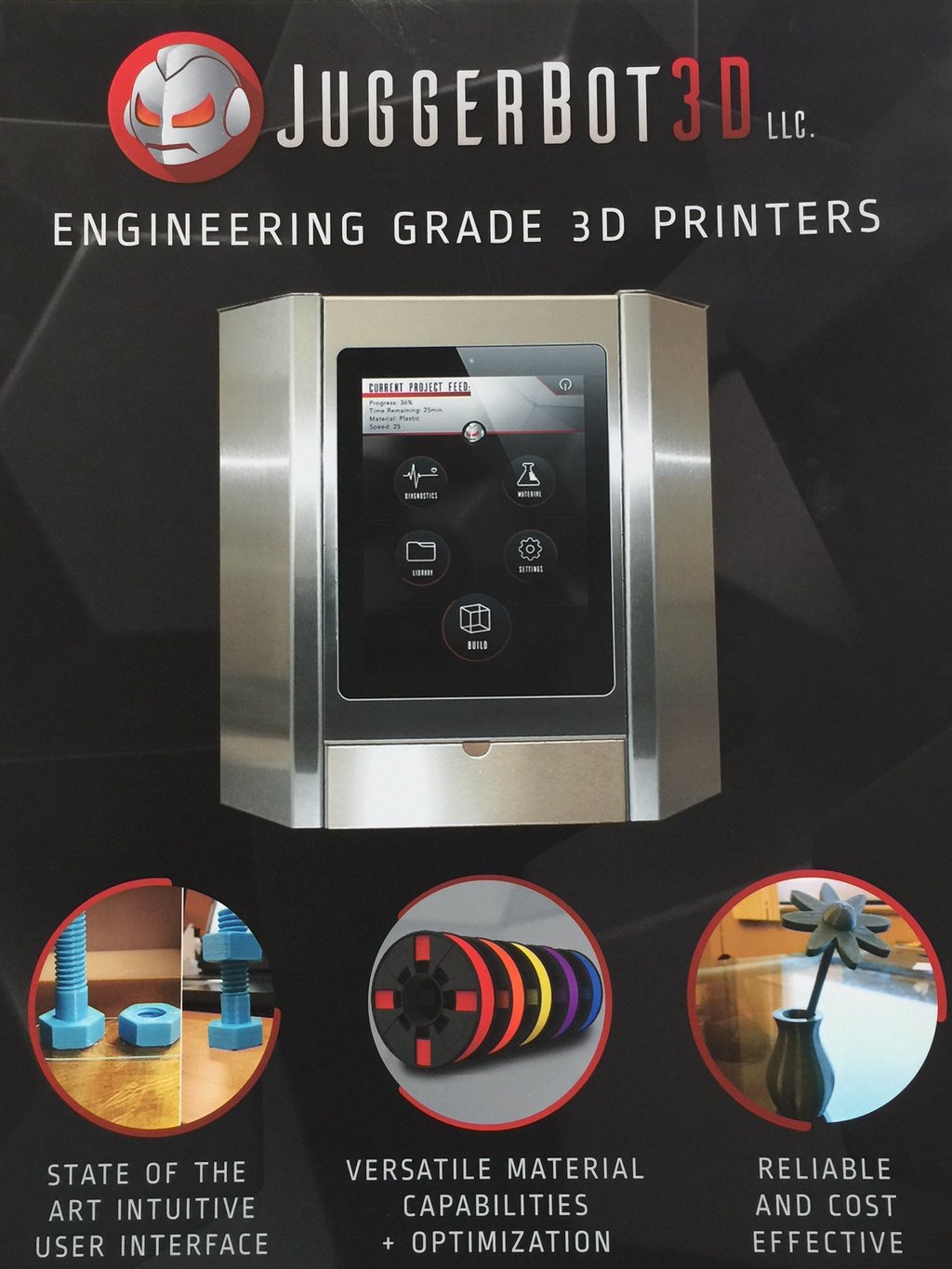

While 3D printing has not completely taken over the market, it is on the rise and big companies, such as automotive and aerospace, are investing in it. Visionary companies like General Electric, Boeing and Airbus recognize the need for evolution. Dan Fernbeck of JuggerBot 3D observed that smaller companies were unsure of 3D printing’s potential for success. Once they saw the benefit of taking risks, they are now starting to catch on. Jeff Keel, CEO of Alios 3D, came from the plastics and steel manufacturing business and now invests in 3D printing. Jeff explained that, 3D printing is the natural growth of what he has always done. “The world is becoming more specialized,” Jeff says, “People are starting to make products and gearing more towards a specialty market.” Mike Szugye of Triptech Plastics has observed that companies are seeking to expand their 3D printing beyond traditional polymers and current materials. They are looking towards printing glass, nylon and other higher strength materials. The owner company of Triptech Plastics, Kent-based Hapco, Inc., invested in the creation of Triptech Plastics after their involvement with the Local Motors 3D printed car.

Not everyone is so keen on adopting 3D printing, however, and the exhibitors admit to encountering resistance. Sometimes, companies view 3D printing as a means of taking away jobs, but Taylor of Printing 3D Parts does not believe that is true. If anything, 3D printing is “enabling lay manufacturers to expand their capabilities and cut costs at the end of the day,” Taylor says. Jeff of Alios 3D believes that the future will be a blend of traditional and new manufacturing, perhaps with an object being 3D printed, then moved into other stages where it is finished with millwork and polishing. “Traditional manufacturing isn’t going to disappear”, Jeff believes, “If it was going to disappear, it would have already gone.” New technology “kills the old technology to a degree, but it doesn’t end. We still need metals. They’re just going to be made in a different form.”

We really enjoyed all the insights we gained from the movers, shakers and makers at Make Youngstown. There is still much more to be said about what we learned, so look out for a part two very soon.

Thanks to the host of the Make Youngstown, Rich Wetzel for allowing us to be part of the event.

Exhibitors at Make Youngstown: